Everything about Premier Aluminum Llc

Everything about Premier Aluminum Llc

Blog Article

Premier Aluminum Llc Things To Know Before You Buy

Table of ContentsThe Single Strategy To Use For Premier Aluminum LlcGetting The Premier Aluminum Llc To WorkIndicators on Premier Aluminum Llc You Should KnowThe smart Trick of Premier Aluminum Llc That Nobody is Discussing

(https://moz.com/community/q/user/premieraluminum)Using low cost and unqualified vendors can trigger high quality concerns, and lost time and cash in the long run. To aid you with the procedure, below are some things to take into consideration when picking the right steel spreading distributor.

As an example, a firm that just uses the investment casting procedure will attempt to offer you on why that process is best for your application. However suppose using the sand spreading process is best for you and your demands? Rather, look for a provider that uses a series of casting processes so the best choice for YOU is chosen

If collaborating with a single source for every one of your spreading needs is very important to you, the provider requires to be diverse in its capacities. When incorporated with various other incorporated capabilities, this can assist simplify and compress the supply base. When picking the right casting distributor, mindful factor to consider ought to be offered to quality, service, and price.

6 Simple Techniques For Premier Aluminum Llc

Purchasers progressively pick spreading providers that have machining capabilities. If the spreading distributor uncovers a concern throughout read review machining, the trouble is solved faster with no conflict over whose mistake it is.

What do you need from your spreading vendor? Are you looking for somebody to simply deliver a metal element to your front door or do you need much more?

Others will exceed the letter of the PO to assist you conserve money and time. Do you have requirements for both ferrous and non-ferrous alloys? Some shops are minimal or specialized. Ensure the distributor can meet all your material or alloy needs to get rid of the requirement for numerous distributors.

7 Easy Facts About Premier Aluminum Llc Described

Study the supplier's web site. Talk to a sales representative or company associate.

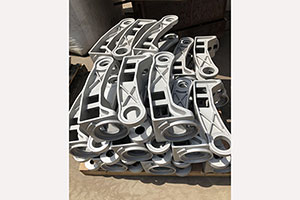

Light weight aluminum is also lightweight and has good deterioration resistance, making it perfect for applications where weight and resilience are important elements. In addition, light weight aluminum casting is a cost-effective method of production, as it requires less energy and sources than various other techniques. Iron casting, on the various other hand, includes putting molten iron right into a mold and mildew to develop a desired shape.

Some Known Incorrect Statements About Premier Aluminum Llc

Iron casting is additionally able to stand up to heats, making it ideal for usage in applications such as engine parts and industrial machinery. Nevertheless, iron spreading can be much more expensive than light weight aluminum spreading as a result of the greater price of basic materials and the energy called for to thaw the iron. When deciding between aluminum spreading and iron casting, it is very important to think about the details needs of the application.

In final thought, both aluminum spreading and iron casting have their own special advantages and drawbacks. There are three sub-processes that fall under the category of die casting: gravity die spreading (or long-term mold and mildew casting), low-pressure die casting and high-pressure die casting. To get to the ended up item, there are 3 primary alloys made use of as die casting material to choose from: zinc, light weight aluminum and magnesium. Report this page